Hazardous wastewater treatment in Bac Ninh using DAF – AUSTRIA and RO ROCHEM – GERMANY technology

Nội dung

1. Scope of work for hazardous wastewater treatment system

- Detailed design of construction and technology for Hazardous Wastewater Treatment in Bac Ninh

- Technical supervision of construction, supply and installation of equipment for the Treatment Plant

- Test operation for the system to meet output standards of type A according to QCVN40/2011

- Prepare working procedures and training for the investor’s operating staff

- Support the investor to explain the technical plan to relevant departments/ministries (if necessary)

2. Water flow to be treated classified by wastewater group

| STT | SYMBOL | WASTEWATER NAME | FLOW (m3/day) |

| 1 | A | Acid wastewater with low pH, metals (and residues) | 70 |

| 2 | B | High pH alkaline wastewater (and sludge) | 30 |

| 3 | C | Grease contaminated wastewater | 50 |

| 4 | D | Wastewater contains cleaning solutions and organic and inorganic chemicals. | 30 |

| 5 | E | Paint contaminated wastewater | 20 |

Results of analysis of some wastewater samples

| Parameter | Wastewater sample | ||||

| Acid (A) | Bazo (B) | Oil mixed (C) | Mixed paint (D) | Mixed cleaning chemicals (E) | |

| Color | 6 | 15 | 5 | 6 | |

| pH | <2 | 10.5 | 8.5 | 8.04 | 5.9 |

| BOD5 | 3588 | 102 | 40 | ||

| COD | 7194 | 11138 | 9714 | 463 | 86.6 |

| COD after filter | 3638 | 8328 | 380 | 65.1 | |

| TSS | 27 | 180 | 57 | ||

| Cu | 1.0 | 0.74 | < 0.02 | 0.14 | |

| Zn | 2.19 | 0.98 | 0.92 | 0.03 | |

| Ni | 0.49 | 1.8 | 0.01 | 5.1 | |

| Fe | 9.1 | < 0.03 | < 0.03 | ||

| Total grease | < 0.3 | 2-5% | 4.8 | 1.5 | |

| Sunfat | < 0.04 | < 0.04 | < 0.04 | < 0.04 | |

| Flo | 2166 | 17.3 | < 0.03 | 51.9 | |

| Amoni | 31.1 | 26.1 | < 0.02 | 86.5 | |

| Total N | 870.2 | 338.8 | 386 | 21.8 | 109 |

| Total P | 120 | 0.08 | 6.4 | 0.16 | 1.2 |

| Cl | 124.8 | 103.5 | 22.7 | 81.7 | |

3. Requirements for wastewater quality after treatment

Requirements for wastewater quality after treatment to meet the permitted standards for industrial wastewater

according to Vietnamese standards (QCVN 40: 2011/BTNMT), pollution treatment reaches the limit value A

4. Hazardous wastewater treatment plan in Bac Ninh

Based on the study of the investor’s requirements for the origin and characteristics of wastewater, the proposed flow rate as well as the requirements for the quality of water after treatment, we propose the following hazardous wastewater treatment plan in Bac Ninh:

First, the wastewater will be classified to select the appropriate preliminary treatment method in the categories

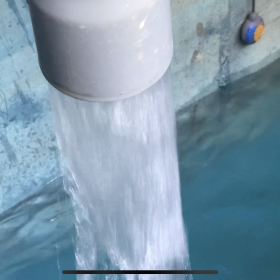

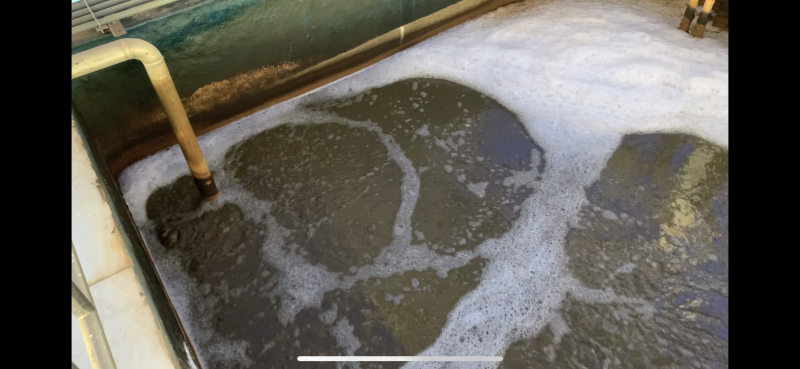

including Fenton, Grease separation or pH adjustment. The wastewater is then treated by the flocculation and sedimentation stage at the mDAF – KWI system (Flocculation and sedimentation tank mDAF Minicell MNC6). Designed in Austria – Made in India, installed by TVTS.

Next, complete wastewater treatment using German RO Rochem technology, installed by TVTS

Rochem RO membrane systems have been used worldwide for over 3 decades, with

a large number of systems operating with wastewater containing high COD / BOD up to

140,000 ppm

5. Actual construction and operation

The inlet water has unstable concentrations of substances, most of which exceed the initial design level. The content of substances sometimes reaches 60,000 ppm. We encountered a very difficult situation to handle.

When the system was designed to handle a load of up to 15,000 ppm, the reality has gone far

Since realizing the problem, we have mobilized the company’s leading technical and technological staff to meet and come up with solutions for situations that may occur.

With the discussion and support from the investor, after more than 1 month we have solved the problem and put the system into operation, treating an average of 200 m3/day and night of wastewater at the factory.

We also received a new project with this customer, SEPTIC TANK WASTEWATER TREATMENT

6. Implementation results

The wastewater after treatment meets the permitted standards for industrial wastewater according to Vietnamese standards (QCVN 40: 2011/BTNMT), and the pollution treatment reaches the limit value of type A