Nội dung

1. What is MET Technology?

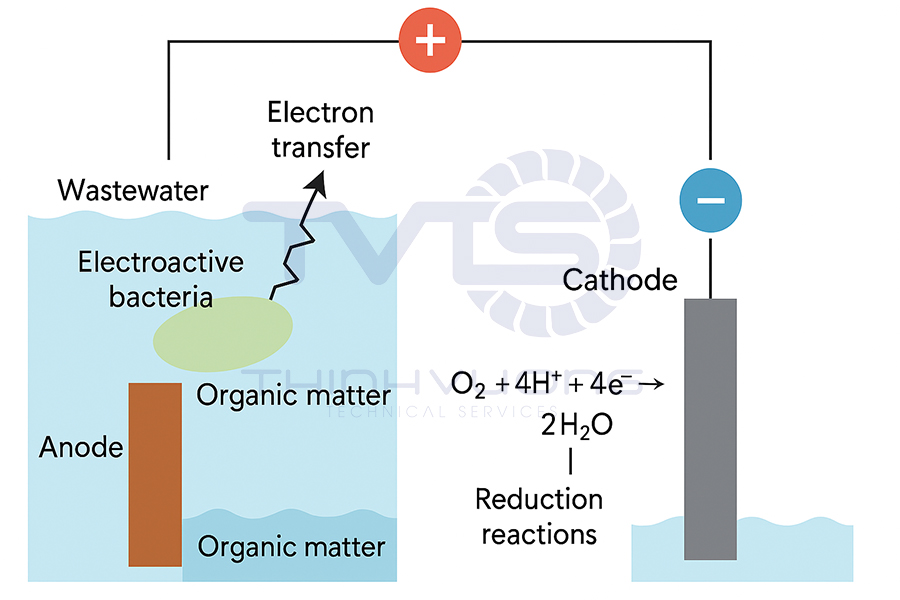

MET (Microbial Electrochemical Technologies) is a wastewater treatment technology that utilizes electroactive microorganisms in combination with electrodes to:

- Degrade organic matter in wastewater.

- Transfer electrons from microbes to electrodes.

- Generate electricity, hydrogen, or valuable chemical products such as acetate, methane, etc.

2. Fundamental Principles of MET

- Electrodes (anode – cathode): Microbes at the anode decompose organic substances and release electrons.

- Electron transfer: Electrons are transported via ion exchange membranes or salt bridges to the cathode, where reduction reactions occur.

Various outcomes:

- MFC (Microbial Fuel Cell): Generates electricity – low power, suitable for powering small devices.

- MEC (Microbial Electrolysis Cell): Produces hydrogen (H₂) or methane (CH₄) through electrochemical processes.

- MES (Microbial Electrosynthesis): Synthesizes valuable chemicals.

- Microbial Desalination Cell: Simultaneously treats wastewater and desalinates water.

3. Applications of MET in Wastewater Treatment

| Area of Application | Main Purpose |

|---|---|

| Domestic, industrial, and medical wastewater treatment | Reduce BOD, COD, pathogens, and heavy metals |

| Desalination | Combines wastewater treatment with salt removal |

| Energy and chemical recovery | Produces electricity, hydrogen, methane, acetate for circular economy |

| Advanced applications | BOD/COD sensors, regeneration of detoxifying agents (e.g. Cr(VI), nitrate) |

4. Advantages and Disadvantages of MET

✅ Advantages:

- Energy-saving: no need for aeration systems

- Recovery of valuable products: electricity, H₂, CH₄, acetate

- Reduced sludge production: less biological sludge than aerobic systems

- Environmentally friendly

⚠️ Limitations:

- High investment cost in electrodes, membranes, and equipment

- Low efficiency when scaled up

- Complex control requirements (voltage, pH, temperature, microbial activity)

- Not yet widely applied in large-scale industrial systems

5. How is MET Different from Traditional Technologies?

- Aerobic (MBR, AAO): Requires oxygen supply, high energy consumption, and produces large amounts of sludge.

- Anaerobic (UASB): Saves energy but does not generate electricity.

- MET: Integrates treatment and energy recovery, reducing operational costs.

6. Roadmap for MET Implementation

- Study natural microbial communities (from sludge, ponds, and wastewater).

- Design electrodes and ion exchange membranes: select carbon-based materials (e.g., graphite).

- Conduct laboratory/pilot testing: determine optimal voltage, temperature, and pH.

- Scale-up: integrate MET with pre-treatment and chemical treatment systems (if needed).

- Monitoring & operation: track current flow and inlet–outlet water quality.

Comparison: MET vs. Conventional Technologies (MBR, AAO, UASB)

A comprehensive technical, economic, and operational comparison between MET and other common wastewater treatment technologies such as MBR, AAO, and UASB, showing differences in mechanism, efficiency, cost, and potential for energy/resource recovery.