Nội dung

- 1. What is an operation log?

- 2. Basic components of an operating log

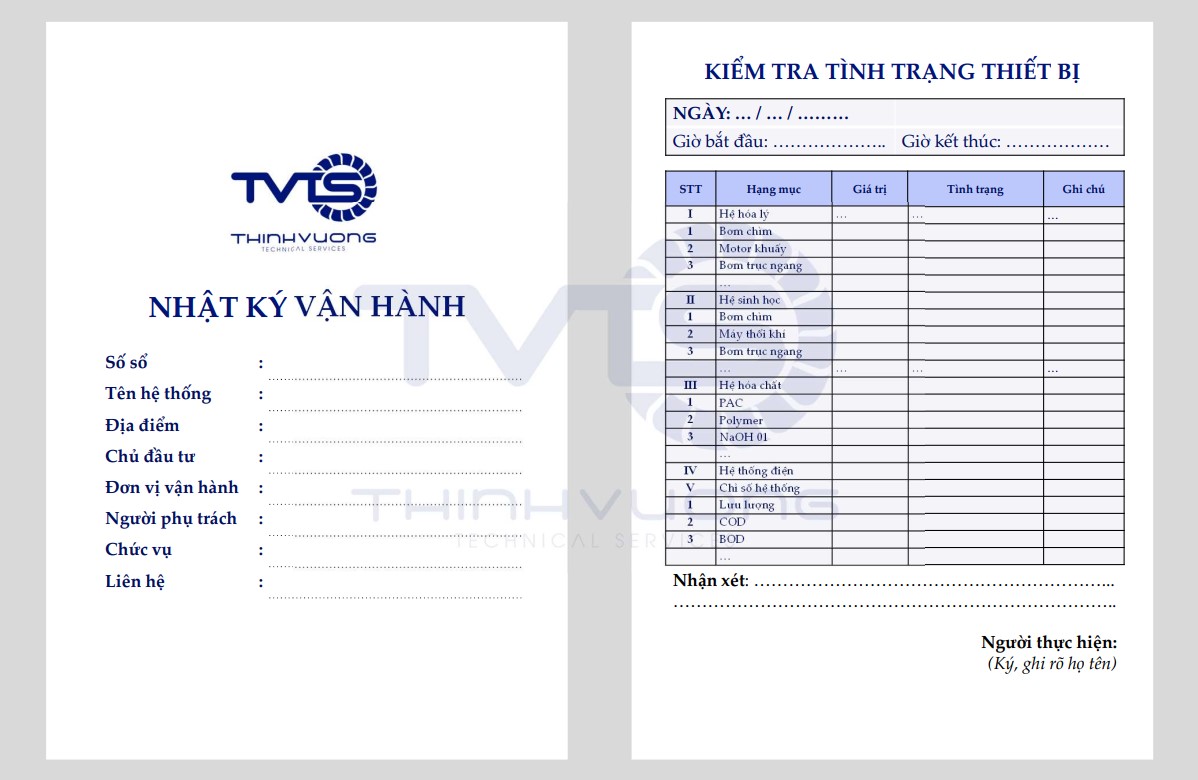

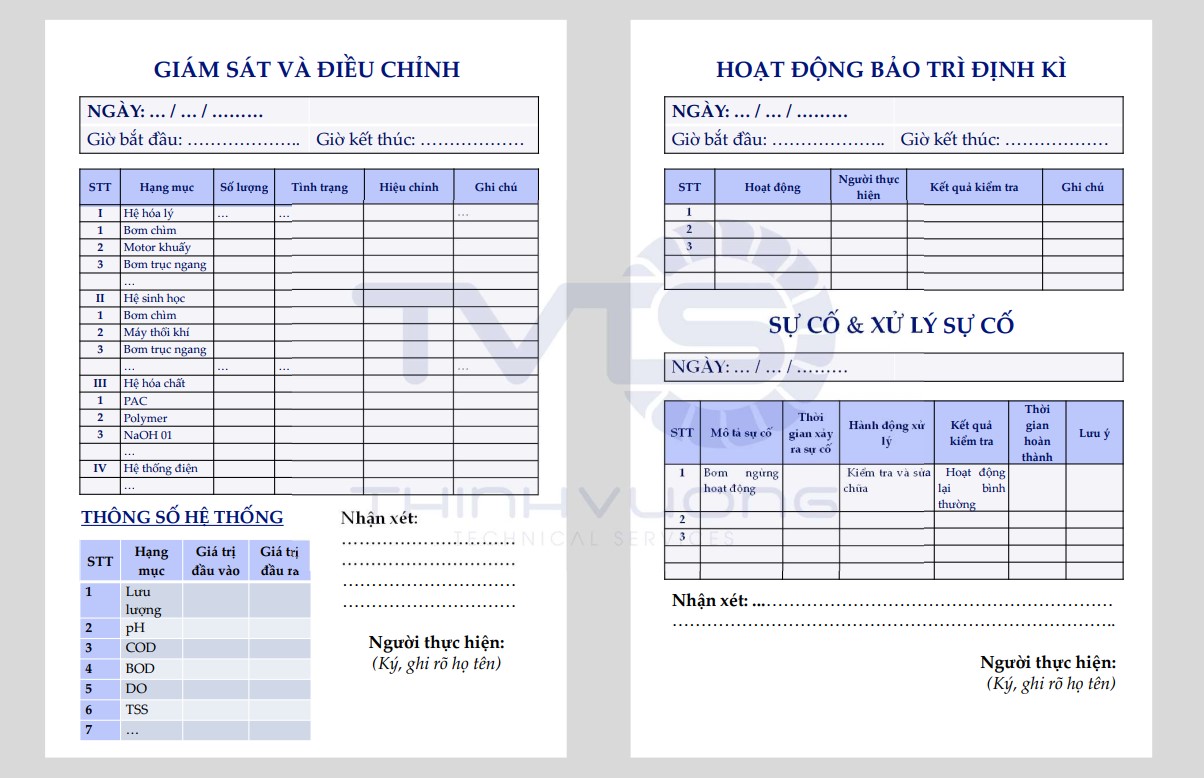

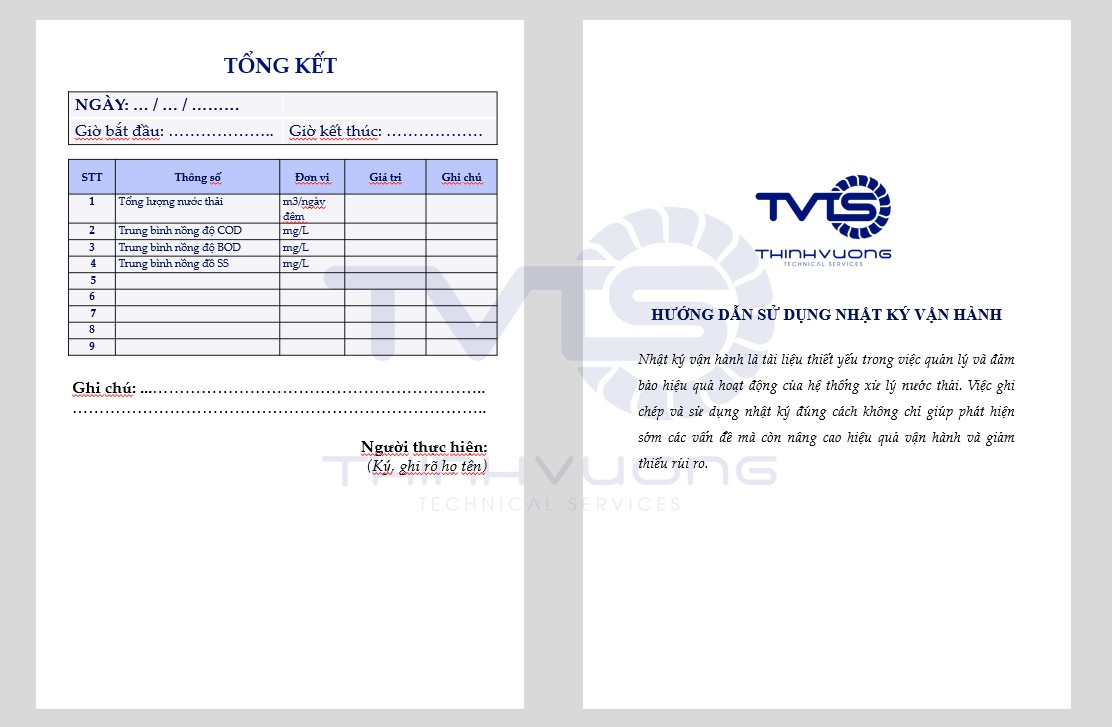

- 3. Some sample tables appear in the water treatment system operation log

- 4. The importance of operating logs

- 5. Notes when using operating logs

- 5.1 Record fully and accurately

- 5.2 Keep records on time

- 5.3 Use clear, concise language

- 5.4 Keep your diary carefully

- 5.5 Delegation and periodic inspection

- 5.6 Record details of incidents and corrective actions

- 5.7 Important parameter notes

- 5.8 Compliance with regulations and standards

- 5.9 Update and maintain electronic logbooks (if any)

- 5.10 Operator training

1. What is an operation log?

An operation log is used to record all information about the work performed during the operation of the water and wastewater treatment system. The operation log helps to control, monitor and accurately assess the status of the system. In addition, it is also a valuable document to trace and find the cause of incidents at the factory.

Download sample wastewater treatment system operation log book

2. Basic components of an operating log

2.1 General information

- Name of treatment system/plant.

- Design capacity (m³/day).

- Management & operation contractor.

2.2 Daily operating parameters

- Time: start time and end time.

- Wastewater flow: m³/day or m³/hour.

- Water quality parameters: pH, temperature, COD, BOD, TSS, temperature, Ec, etc.

- Chemicals used: Chemical type, concentration, dosage (kg or liter).

- Energy consumption: Electricity (kWh), fuel, etc.

2.3 Control of incidents

- Description of the problem (pump failure, blockage, floating sludge, etc.).

- Time of occurrence and initial cause.

- Action taken.

- Time of completion of problem resolution

2.4 Maintenance & Service

- Name of maintenance equipment.

- Time of implementation and results.

- Notes on replacement components and equipment (if any).

2.5 Comments

Comments & evaluation of daily operation efficiency. Propose solutions to improve operation efficiency.

2.6 Confirmation Signature

Signature confirmed by the performer, recorder, manager or supervisor.

3. Some sample tables appear in the water treatment system operation log

3.1 Check the operating status of the equipment

| STT | Time | Category | Value | Status | Note |

| I | Physical chemistry | … | … | … | |

| 1 | Submersible pump | ||||

| 2 | Stirring motor | ||||

| 3 | Horizontal shaft pump | ||||

| … | |||||

| II | Biological system | ||||

| 1 | Submersible pump | ||||

| 2 | Air blower | ||||

| 3 | Bơm trục ngang | ||||

| … | … | … | … | ||

| III | Chemical system | ||||

| 1 | PAC | ||||

| 2 | Polymer | ||||

| 3 | NaOH 01 | ||||

| … | |||||

| IV | Electrical system | ||||

| V | System index | ||||

| 1 | Traffic | ||||

| 2 | COD | ||||

| 3 | BOD | ||||

| … |

3.2 Monitoring and adjustment

| STT | Device | Time | Quantity | Current Status | Correction | Note |

| I | Physical chemistry | |||||

| 1 | Submersible pump | |||||

| 2 | Stirring motor | |||||

| 3 | Horizontal shaft pump | |||||

| … | ||||||

| II | Biological system | |||||

| 1 | Submersible pump | |||||

| 2 | Air blower | |||||

| 3 | Horizontal shaft pump | |||||

| … | ||||||

| III | Chemical system | |||||

| 1 | PAC | |||||

| 2 | Polymer | |||||

| 3 | NaOH 01 | |||||

| … | ||||||

| IV | Electrical system |

3.3 Daily operating parameters

| STT | Category | Time | Input value | Output value | Note |

| 1 | Lưu lượng | ||||

| 2 | pH | ||||

| 3 | COD | ||||

| 4 | BOD | ||||

| 5 | DO | ||||

| 6 | TSS | ||||

| 7 | Ec | ||||

| 8 | … | ||||

| 9 | Sludge treatment |

3.4 Periodic maintenance activities

| Maintenance date | Work | The performer | Test results | Note |

| … | … | … | … | … |

| … | … | … | … | … |

3.5 Problems and solutions

| Date | Description of the problem | Time of incident | Action to take | Result | Completion time | Note |

| … | Stop the pump | … | Check and repair | Back to normal | … |

4. The importance of operating logs

4.1 Monitor and evaluate operations

Record system operating parameters. Detect problems early for timely handling.

4.2 Provide evidence data

A transparent document when environmental management agencies request inspections. A basis for resolving disputes or complaints about treatment quality.

4.3 Support maintenance processes, optimize operating costs

The data system helps plan periodic maintenance. Detect problems that reduce system performance. Have plans to improve and enhance system treatment efficiency. Optimize and reduce operating costs.

4.4 Raise awareness of responsibility

Detailed recording helps operators raise awareness and be more proactive in their work. Comply with procedures and ensure quality.

5. Notes when using operating logs

5.1 Record fully and accurately

- All operating parameters, incidents, and maintenance activities must be recorded clearly and accurately immediately after they occur.

- Avoid omissions or inaccurate recordings as this may affect later analysis and troubleshooting.

5.2 Keep records on time

- Information should be updated in real time to ensure accuracy and continuity.

- Do not record at the end of the day or shift to avoid errors.

5.3 Use clear, concise language

- Avoid using complex technical terms without explaining clearly.

- Be concise but still have enough ideas for others to understand when reading again.

5.4 Keep your diary carefully

- The logbook should be stored in a dry, safe place to avoid loss or damage.

- If using an electronic recording system, ensure that the data is backed up regularly.

5.5 Delegation and periodic inspection

- Designate a responsible person to keep records to ensure consistency.

- Managers or supervisors should periodically review logs to promptly detect errors or unusual information.

5.6 Record details of incidents and corrective actions

- When an incident occurs, describe in detail the situation, the cause (if identified), and the corrective steps taken.

- This will help improve future incident handling.

5.7 Important parameter notes

- Parameters such as flow, pH, DO, COD, BOD, and chemicals used should be carefully checked and recorded.

- Deviations in these parameters can be an indication of system failure.

5.8 Compliance with regulations and standards

- Ensure that the log content complies with the relevant environmental regulatory body or ISO standards.

- Some industries require logs to be retained for a certain period of time for audit purposes.

5.9 Update and maintain electronic logbooks (if any)

- If you use operations management software, make sure the system is regularly maintained and updated.

- Check the security of your data to avoid loss or alteration.

5.10 Operator training

- Ensure all operators are trained in proper log keeping.

- Increase their sense of responsibility so they see the importance of logs in the operation process.

Download sample: wastewater treatment system operation tracking book sample